Why Ergonomics Is Important in Sterile Processing

- joelhughes

- Jul 19, 2024

- 3 min read

Ergonomics, the study of people's efficiency in their working environment, is particularly critical in the field of sterile processing. This area demands precision, safety, and efficiency, all of which are significantly impacted by ergonomic principles.

Let's look at why ergonomics is important in sterile processing and how it can improve the overall quality of work in this field.

Preventing Injuries and Strains

Sterile processing technicians are responsible for handling various instruments and equipment that are often heavy, awkwardly shaped, or require repetitive movements. Without proper ergonomic practices, these tasks can lead to injuries and strains on the body, particularly in the hands, arms, shoulders, and back.

This strain can result in long-term health issues and may even lead to technicians having to take time off work for recovery. By implementing ergonomic principles, such as proper body mechanics and using assistive devices, you can reduce the risk of injuries and strains, creating a safer working environment for technicians.

Increasing Efficiency

In sterile processing, time is of the essence, as every minute counts when preparing and distributing instruments for procedures. By utilizing ergonomic practices, such as organizing workstations and streamlining processes, technicians can improve their workflow and productivity. This not only allows for a more efficient use of time but also reduces the risk of errors that may occur from rushed or repetitive tasks.

Reducing Costs

Incorporating ergonomic designs and optimizing the footprint of each system ensures the material is used as efficiently as possible, reducing system costs. And by limiting the footprint of each system, inventory storage areas can be used more efficiently, leading to improved productivity.

Promoting Quality Control

Sterile processing is a highly regulated field, with strict standards and guidelines that ensure patient safety. By incorporating ergonomic principles into their work, technicians can maintain a higher level of accuracy and precision. This accuracy is particularly crucial when it comes to instrument assembly and sterilization, as any errors or contamination could have serious consequences for patients.

Enhancing Comfort and Well-Being

Working in sterile processing can be physically and mentally demanding, with technicians often standing for long periods in a fast-paced and high-stress environment. Incorporating ergonomic practices can help reduce physical strain and discomfort, leading to improved overall well-being. This reduction can also have a positive impact on mental health, as technicians may experience less strain and fatigue when working in an ergonomically friendly environment.

Improving Job Satisfaction

With less strain, injuries, and errors, technicians can feel more confident and satisfied in their work. This confidence can lead to improved job performance and morale, creating a positive work culture within the sterile processing department. By prioritizing ergonomics, employers can show their commitment to the well-being of their employees, leading to increased job satisfaction and retention rates.

Ergonomics plays a significant role in the field of sterile processing. By implementing ergonomic principles, employers can improve safety, efficiency, and overall quality of work for technicians. This not only benefits the employees but also has a positive impact on patient outcomes and the healthcare industry as a whole. Employers must prioritize ergonomics in their sterile processing departments to ensure the well-being of their employees and provide the best possible care for patients.

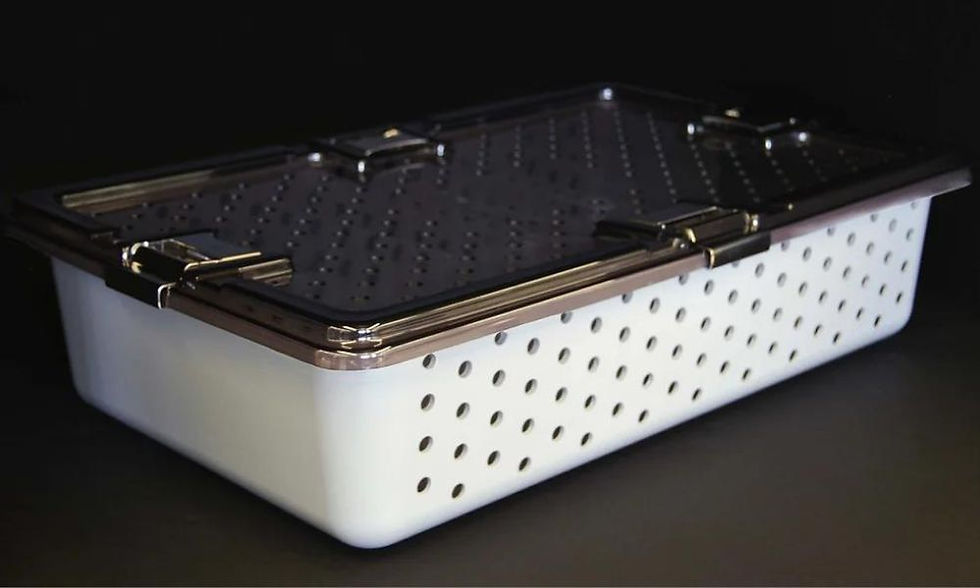

If you need a surgical instrument tray for your medical facility or hospital, Legacy Medical Solutions can help. Our team of experts can work with you to design and manufacture the perfect tray for your specific needs, taking into account ergonomic principles to ensure efficiency and ease of use for your technicians. Contact us today to learn more about our services!

Comments